Pece & Žíhání, nitridace

Nabízíme žíhání a nitridování materiálů ve vlastním provoze:

- Žíháme těžké konstrukční celky až do 40t váhy. Složité svařované rámy můžeme žíhat na odstranění pnutí při typických teplotách od 500-550°C.

- Nadrozměrné kusy žíháme ve speciální peci s pojezdem až do 10m délky kusu.

- Žíháme náročné a složité kusy do 2m délky a chladíme s připojenou chladící sestavou tak, aby jsme odstranili zbytky perlitu z odlitků a to dle dané teplotní křivky.

- Nitridujeme do 2m délky ve speciální peci s pojezdem, např. částí forem pro tlakové a komorové lití dále náhradní- nejvíce zatěžované částí forem

- Taktéž jsme schopni nanášet speciální hmotu až do 1100°C, jako ochrana proti opotřebení, zejména určenou pro slévárenské lžíce.

- is used for the heat treatment of welded parts up to a width of 3 metres and a depth of 6 metres

- asymmetric welded constructions should annealed or stress-relieved before machining

- freshly fired cut sheets can also be stress-relieved

- we can anneal and subsequently cool down demanding parts; e.g. to remove undesired alloy fractions in castings, or to follow given temperature diagrams

- the furnace control technology is digital and allows to follow complex temperature profiles

- a USB hub allows to document, print or send the actual measured values

- diverse temperature sensors in different positions are calibrated to document temperature differences of 0,2°C

bogie hearth furnace

top-hat furnace

- is used for the heat treatment of heavy parts up to 40 tons, e.g. mould frames can be interstage annealed or stress-relieved at common temperatures between 500 and 550 °C

top-hat furnace

nitriding furnace

- is used for nitriding parts with lengths up to 2 metres, e. g. components of casting dies, complete shot sleeves or other wearing parts

- special coatings can be burned-in up to 1100 °C, e. g. as wear protection of casting ladles

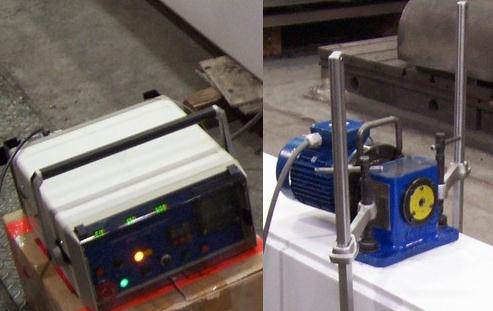

- is used to stress-relieve extra large parts

- the process is electrical controlled by measuring the vibration amplitude with a sensor

- doesn't cause any scale or structural changes

- is faster and less expensive than heat treatment

stress-relieve by vibrating

walk-in sandblasting system

- we can sandblast heat treated parts to obtain a clean surface

- we can sandblast finished welded constructions and complete machines to obtain an even and reactive surface, e. g. before painting

- we don't sandblast with "sand" but special blasting abrasives

- the chamber is extra large to sandblast even large parts

- the chamber is situated as far as possible from our paint shop to avoid any entrapment of blasting abrasives or dust

- a special compressor unit provides high power compressed air

- the in-house sandblasting system allows short delivery times for our clients

- the large sandblasting system is enhanced by several manual blasting equipments for smaller parts

walk-in sandblasting system